Most of the B-25 still existing nowadays are equipped with readily available Martin turret of a type never used on the B-25. In order to complete even more our B-25 we did the acquisition of an authentic Bendix gun turret in Australia thanks to a generous donator. As nothing is perfect, this turret was incomplete, but we had a base to start a restoration.

Bendix upper turret description

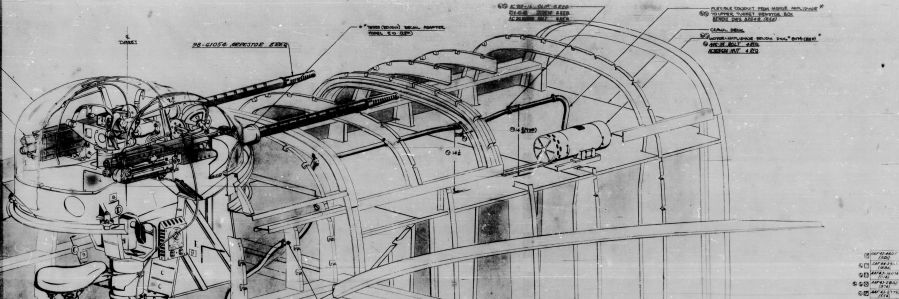

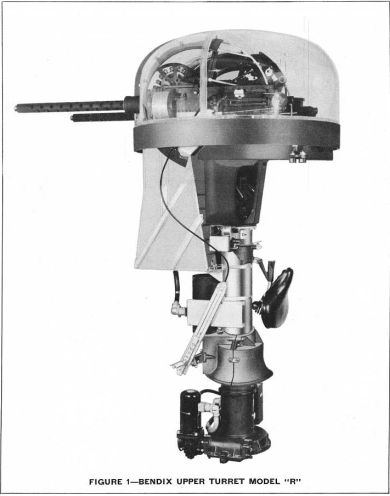

The North American B-25 Mitchell was one of the best medium bombers used by the Allies. Its defensive armament was certainly among the most effective. The first Mitchell model relied on the Bendix top turret, which was fitted in the rear fuselage for all-round defense. When two waist guns were provided for later models, the Bendix turret was moved forward to a position just behind the pilot's cabin.

The Bendix mid-upper turret was electrically powered by the Amplidyne system, in which two infinitely controllable motor-driven generators controlled two drive motors, one for rotation and the other for elevation. The gunner's control handles were turned to the left for left rotation and right for right, while a twisting movement elevated and depressed the guns. At the top of each handle was a high-speed button for rapid movement when changing targets. The turret was by no means roomy: once in the turret the gunner was quite restricted in his movements. His field of view was also not ideal, as he could only see to the front.

Dismantling and repairs

When we took delivery of the turret components purchased in Australia, we realized the scale of the task ahead. It's hard to ignore the damage caused by over 75 years of exposure to the elements. Some sub-assemblies are badly damaged, broken, or reduced to an agglomerate of elements welded together by corrosion. Curiously, some parts are in remarkable condition once they have been cleaned. The first job was to dismantle the turret so that each component could be repaired, if repairable. Easy said but not easily done: nut and bolt assembly (or any other assembly) that has been exposed to the elements for so long is no longer very cooperative about being taken apart. Patiently, and using a variety of techniques, we managed to dismantle a large number of parts, which are then sorted and, for those that are still usable, repaired.

Documentation and acquisitions

Various reference manuals have been acquired. This documentation enabled us to make an inventory of salvageable components and to list the many parts still needed to reconstitute a complete turret. It has also enabled us to list the screws, bolts and other fittings needed to reassemble the turret.

Many of the missing parts have been purchased from Fred Bieser, a turret restoration specialist from Lithonia, Georgia (USA). Some other parts have been acquired from Sandbar Mitchell, who are rebuilding two turrets: a functional one for their B-25 and a static one for a museum. Finally some parts need to be manufactured. This is mainly the case with bakelite components, but also with some small parts such as inserts.

Re-assembly

Assembling the turret is not necessarily the easiest stage, as the assembly of various components of various origin sometimes brings to light problems that will need to be resolved. Even if the Bendix upper turret has only been in use for a few years, some parts exist in various versions that are not always compatible. This, combined with the scarcity of parts, means that some compromises have to be made.

Functional or static?

It's all a question of means and know-how. At the moment, the turret is assembled with the idea of making it work (at least rotation/elevation). But the sheer number and scarcity of parts means that the cost of refurbishment is skyrocketing. That's why donations are so important.

Bendix upper turret description

The North American B-25 Mitchell was one of the best medium bombers used by the Allies. Its defensive armament was certainly among the most effective. The first Mitchell model relied on the Bendix top turret, which was fitted in the rear fuselage for all-round defense. When two waist guns were provided for later models, the Bendix turret was moved forward to a position just behind the pilot's cabin.

The Bendix mid-upper turret was electrically powered by the Amplidyne system, in which two infinitely controllable motor-driven generators controlled two drive motors, one for rotation and the other for elevation. The gunner's control handles were turned to the left for left rotation and right for right, while a twisting movement elevated and depressed the guns. At the top of each handle was a high-speed button for rapid movement when changing targets. The turret was by no means roomy: once in the turret the gunner was quite restricted in his movements. His field of view was also not ideal, as he could only see to the front.

Dismantling and repairs

When we took delivery of the turret components purchased in Australia, we realized the scale of the task ahead. It's hard to ignore the damage caused by over 75 years of exposure to the elements. Some sub-assemblies are badly damaged, broken, or reduced to an agglomerate of elements welded together by corrosion. Curiously, some parts are in remarkable condition once they have been cleaned. The first job was to dismantle the turret so that each component could be repaired, if repairable. Easy said but not easily done: nut and bolt assembly (or any other assembly) that has been exposed to the elements for so long is no longer very cooperative about being taken apart. Patiently, and using a variety of techniques, we managed to dismantle a large number of parts, which are then sorted and, for those that are still usable, repaired.

Documentation and acquisitions

Various reference manuals have been acquired. This documentation enabled us to make an inventory of salvageable components and to list the many parts still needed to reconstitute a complete turret. It has also enabled us to list the screws, bolts and other fittings needed to reassemble the turret.

Many of the missing parts have been purchased from Fred Bieser, a turret restoration specialist from Lithonia, Georgia (USA). Some other parts have been acquired from Sandbar Mitchell, who are rebuilding two turrets: a functional one for their B-25 and a static one for a museum. Finally some parts need to be manufactured. This is mainly the case with bakelite components, but also with some small parts such as inserts.

Re-assembly

Assembling the turret is not necessarily the easiest stage, as the assembly of various components of various origin sometimes brings to light problems that will need to be resolved. Even if the Bendix upper turret has only been in use for a few years, some parts exist in various versions that are not always compatible. This, combined with the scarcity of parts, means that some compromises have to be made.

Functional or static?

It's all a question of means and know-how. At the moment, the turret is assembled with the idea of making it work (at least rotation/elevation). But the sheer number and scarcity of parts means that the cost of refurbishment is skyrocketing. That's why donations are so important.

Above: The Bendix upper turret model "R" as used in B-25J models. Under: the turrets parts acquired in Australia. In fact there are parts from two turrets in the lot

Above: After a lot of work the turrets parts are dismantled. Under: tthe parts that can still be used are repaired.