Slingsby T3 Dagling (Zögling)

The Zögling (Pupil) primary trainer was designed in the mid twenties by Fritz Stamer and Alexander Lippisch who worked together at the Aeronautical Department of the Rhön-Rossitten Gesellschaft ( RRG). Strongly built with a solid wooden keel able to stand the rough and tumble of training, the Zögling were using from 1926 in the schools on the Wasserkuppe and at Rossitten and the drawing were published and sold all over Europe and the world.

Drawings for a version with steel tubes to support the tail were produced by Wolf Hirth. The drawings of this modified Zögling made their way, via the United States, to the London Gliding Club and Reginald Foster Dagnall whose RFD company manufactured it as the RFD Primary. Dagnall made some alterations to the design and the glider was renamed “Dagling”, combination of Dagnall and Zögling. Fred Slingsby took over construction in 1934 and production continued up to the outbreak of World War II. The Primary should not be confused with the similar T.38 Grasshopper which was produced for the Air Training Corps in the 1950s.

Of basic design, the Daglng was easy to build and to repair. On the minus side the Daglng had no provision for trimming ballast, which means a significant diffference to stability and sensitivity of the elevators depending of the weight of the pilot. The Dagling was nevertheless the forerunner of all the others primary gliders like the SG-38 and the SABCA Junior.

The remains of the BAPA machine were by an enthusiast who gave it free of charge to the association. No information is available about its origin.

Status

Fully rebuilt.

Currently on display at WOW

.

Note: Alexander Lippisch began his aeronautical career with this very basic design but specialized later in swept-wing and tailless designs like the Messerschmidt Me-163 rocket fighter and the Lippisch P-13 ramjet delta interceptor.

Drawings for a version with steel tubes to support the tail were produced by Wolf Hirth. The drawings of this modified Zögling made their way, via the United States, to the London Gliding Club and Reginald Foster Dagnall whose RFD company manufactured it as the RFD Primary. Dagnall made some alterations to the design and the glider was renamed “Dagling”, combination of Dagnall and Zögling. Fred Slingsby took over construction in 1934 and production continued up to the outbreak of World War II. The Primary should not be confused with the similar T.38 Grasshopper which was produced for the Air Training Corps in the 1950s.

Of basic design, the Daglng was easy to build and to repair. On the minus side the Daglng had no provision for trimming ballast, which means a significant diffference to stability and sensitivity of the elevators depending of the weight of the pilot. The Dagling was nevertheless the forerunner of all the others primary gliders like the SG-38 and the SABCA Junior.

The remains of the BAPA machine were by an enthusiast who gave it free of charge to the association. No information is available about its origin.

Status

Fully rebuilt.

Currently on display at WOW

.

Note: Alexander Lippisch began his aeronautical career with this very basic design but specialized later in swept-wing and tailless designs like the Messerschmidt Me-163 rocket fighter and the Lippisch P-13 ramjet delta interceptor.

Above: a Dagling in 1939

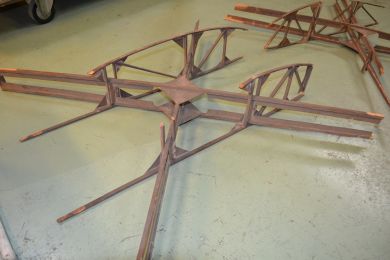

Here under: the Dagling we received was more a jigsaw than a glider and much work was needed to rebuilt it.

Here under: the Dagling we received was more a jigsaw than a glider and much work was needed to rebuilt it.

Here under: if the fuselage was easy to rebuilt, the tail needed lots of repairs and the wings had to be completely rebuilt using the original spars and a few structural components.

|

T3 Dagling characteristics : |

|

| Length : 5,45m |

|

|

Wingspan : 10,35 m |

|

|

Wing area : 15,06 m² Wing Profil : Göttingen 326 |

|

|

Empty weight: 82 kg Gross weight: 173 kg |

|

.jpg)